+886-3-5590169

+886-3-5574282

info@syskey.com.tw

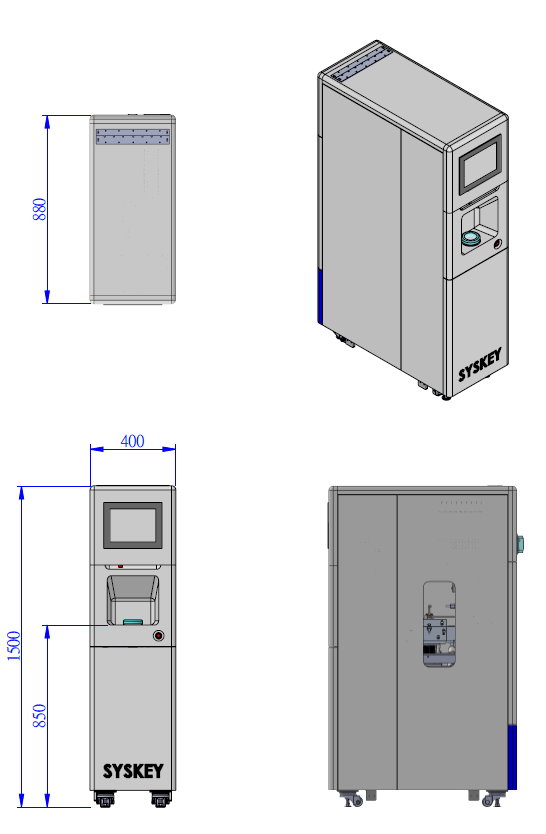

超小型实验线

为了因应快速的实验和有限的空间,SYSKEY针对2吋玻璃和矽晶圆基板开发出极小型设备。 Mini Line是用于小批量生产的实用制造系统。通过使得更容易生产少量的元件,这是研究人员期望的新型研究和开发,并且可实现少量的多样化产品,而且其设备体积小不占用空间。

对于SYSKEY的Mini Line系统,包含热蒸镀、溅镀、电浆辅助式化学气相沉积、电浆辅助式原子级沉积、干蚀刻机、感应耦合电浆蚀刻、电子束蒸发,并可以精准的控制制程气体与监控其数据(压力、载台温度),并提供高品质的薄膜。

| Multi-Target Sputter | Thermal Evaporation | PECVD |

|

|

|

| PEALD | Reactive-Ion Etching | Inductively Coupled Plasma Etching |

|

|

|