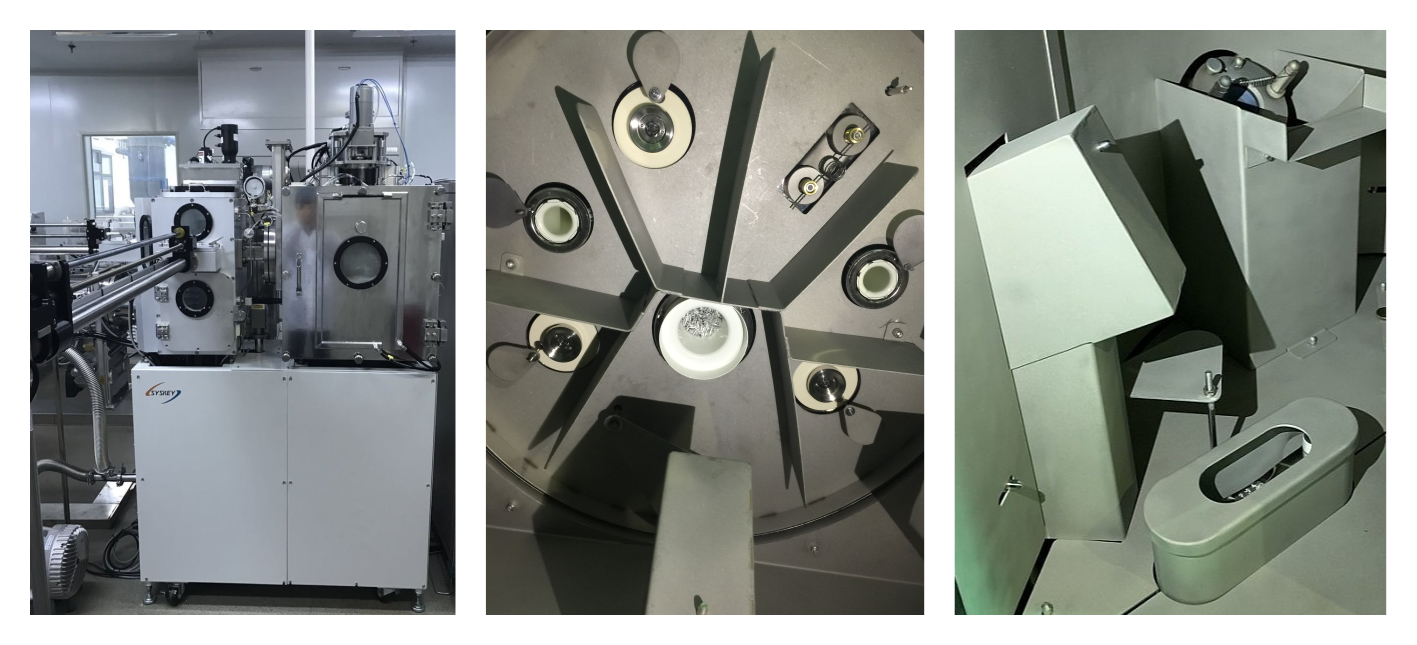

Thermal Evaporation

The materials are placed in a resistive heat source in vacuum environment to evaporate directly to the substrate, where they condense back to a solid state form a thin film.

Metal Thermal

Thermal evaporation system is the most common method of Physical Vapor Deposition (PVD). It is one of the simplest forms of PVD. The evaporation source using electric heating can be used to deposit most organic and inorganic thin films, among which the resistance Joule method is the most common. The advantage of these evaporation sources is that they can provide a simple method of thin film deposition, and current flows through the resistance element that needs to deposit material, thereby heating the material.

When the temperature is heated so that the vapor pressure of the deposited material exceeds the temperature of the vacuum chamber, the material will begin to evaporate and deposit onto the substrate. For SYSKEY's system can control the evaporation rate, the film thickness and uniformity is less than +/- 3%.

Ion source can be used to clean and accelerates the vaporized coating material, and the ion source helps deposit and compact the deposited films during the material deposition process.

| Applications | Chamber |

|

|

| Configurations and benefits | Options |

|

|