ALD

It can be considered as a special type of chemical vapor deposition. The majority of ALD reactions use two or more chemicals called precursors.

Plasma ALD

|

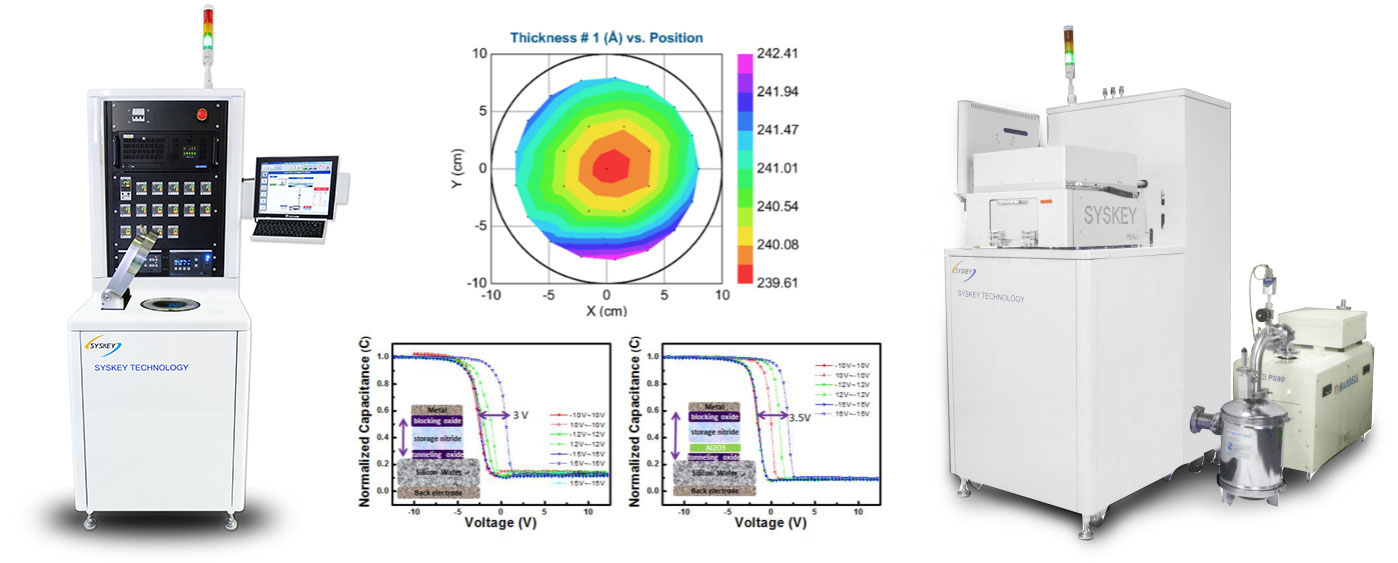

Plasma enhanced atomic layer deposition (PEALD) is an advanced method based on conventional ALD by using plasma as a condition to crack precursor materials instead of relying only on the thermal energy from the heated substrate. This process allows fabricating the conformal thin films of various materials with atomic-scale control without high temperature required to deliver the necessary activation energy. For SYSKEY's system can control the plasma and ALD process, the film thickness and uniformity is less than +/- 1% |

|

SONOS Memory / MOS devices demo

SONOS Memory / MOS devices demo

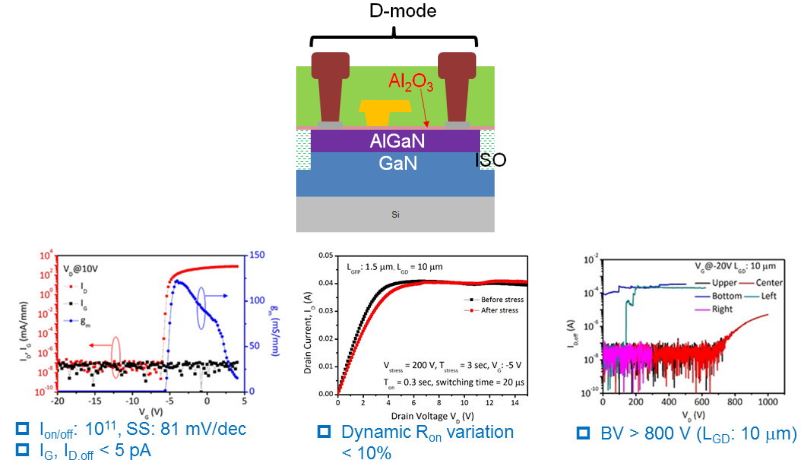

High-K films for GaN power device

| Applications | Chamber |

|

|

| Configurations and benefits | Options |

|

|